fig : DC-DC boost converter test setup to find the converter characteristic

at different operating regions (2021 December)

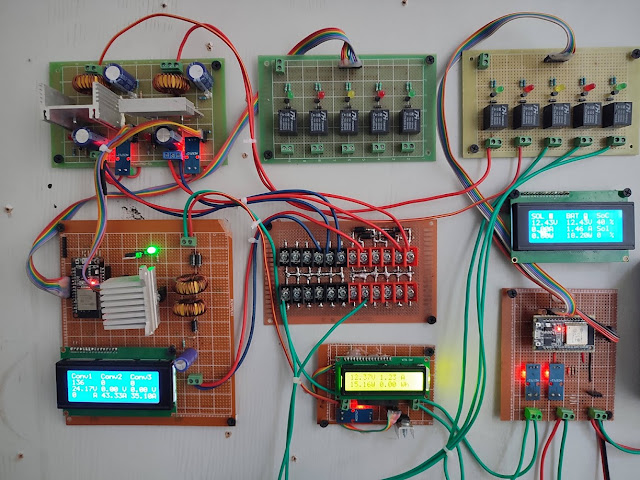

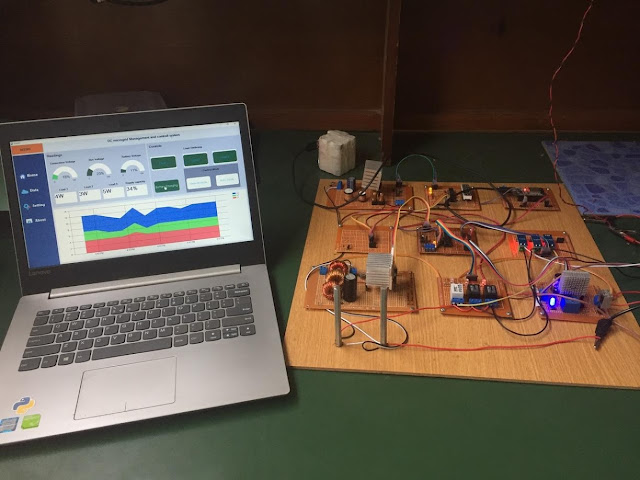

fig : Initial microgrid setup (2021 November)

fig : Lora based energy meter (2021 October)

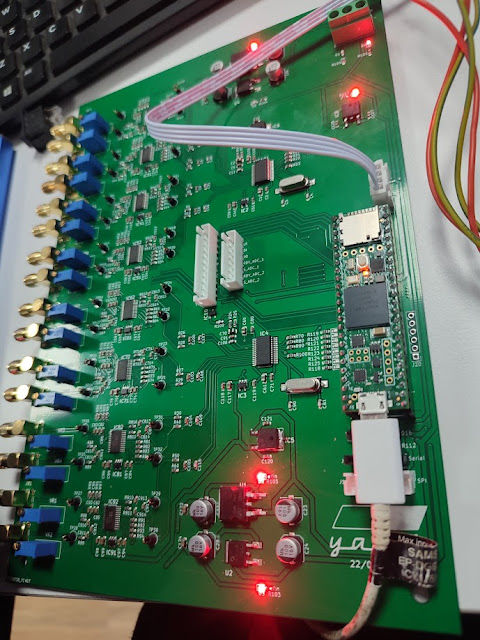

fig : Energy meter firmware development and testing (2021 September)

fig : energy meter developed in Kathmandu university

microgrid lab (2021 September)

fig :Programmable relay board developed at Kathmandu university

microgrid lab (2021 September)

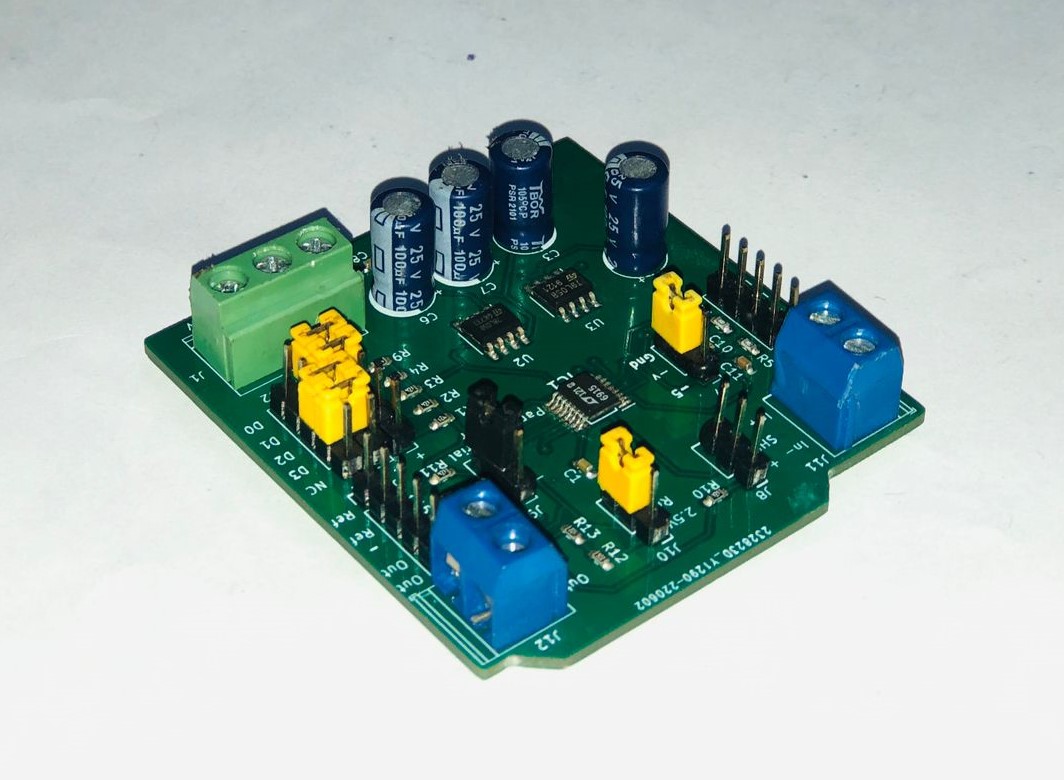

fig : Energy meter PCB board (2021 September)

fig : MPPT charge controller PCB board (2021 September)

fig :Programmable relay board (2021 September)

fig : MPPT charge controller test (2021 September)

fig : Lora based Energy meter network test site at Gorkha district (2021 August)

fig : Lora mesh network test site at Kathmandu University premises (2021 July)

fig : LoRa Mesh network test node

fig : LoRa mesh simulation on NS2 software (2021 July)

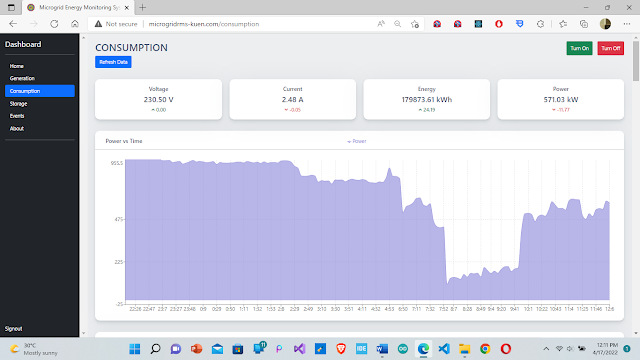

fig : energy monitoring website developed for Marangburu microgrid

located at Biratnagar Nepal (2021 july)

fig : LoRa mesh software development (2021 June)

fig : DC- DC bidirectional Buck-Boost converter testing (2021 June)

fig : LoRa energy meter preliminary hardware test (2021 June)

fig : SPWM inverter hardware setup (2021 May)

fig : Wifi based energy meter test (2021 May)

fig : Experiment to measure phase angle between current and voltage

I was easily able to detect phase angle and was trying to find a

way to determine whether the measured angle is lead or lag via code. (2021 March)

fig : SPWM pulses generated for inverter (2021 March)

fig : MPPT solar charge controller experimental setup

fig : A4 size CNC plotter (2021 February)

fig : CNC plotter result (2021 February)

fig : CNC plotter result (2021 February)

fig : CNC plotter result (2021 February)

fig : CNC plotter result (2021 February)

fig : DVD driver CNC plotter 2021 (January)

fig : DVD driver CNC plotter (2021 January)

fig : work table (2021 January)

fig :Motor control lab KU DOEEE (2020 November)

fig: Priority based load sharing simulation of DC-DC converters

(2021 October)

fig : project framework development MS by research (2020 march )

Bachelors in Electrical and Electronics Engineering Graduation

fig : Internship SCADA design for Upper Mai Hydropower ( 2019 October)

fig : Internship HMI design (2019 October)

fig : Internship HMI design (2019 October)

fig : Bottle filling plant PLC setup (Internship 2019 October)

fig : Internship PLC programming setup (2019 October)

fig : Microcontroller training program (2019 August)

fig : fourth year project setup (2019 August)

fig : fourth year project setup (2019 August)

fig : Rural Nepal household load profile survey (2019 4th year)

fig : Light intensity controller software ( 2019 4th year)

fig : Relay switching board ( 2019 4th year)

fig : 8 channel nrf24 based wireless receiver ( 2019 4th year)

fig :Nrf24 based remote controller ( 2019 4th year)

fig : esp32 SD card data logger ( 2019 4th year)

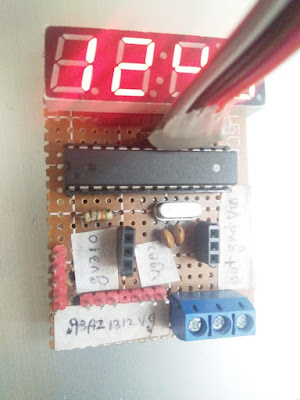

fig : ATmega328 based boost converter controller

( 2019 4th year)

fig : LM35 based seven segment temperature

measurement circuit ( 2019 4th year)

fig : IOT based contactor controller

(2019 4th year)

fig : Energy meter (2019 4th year)

fig : microcontroller training program (2018 3rd year)

fig : Patient monitoring system for hospitals

(3rd year project 2018)

fig : Patient monitoring system for hospitals

(3rd year project 2018)

fig : Optical pulse sensor serial plot

(3rd year 2018)

fig : IOT based waste management system

(3rd year 2018)

(IT meet Hardware hackathon)

fig : ATmega328 based clock (3rd year 2018)

fig : Power supply design for electronics projects

(3rd year 2018)

Fig : IOT based home automation board

(3rd year 2018)

fig : Bottle hackathon 2018

(3rd year 2018)

fig : Line following robot sensor array development

(2nd year 2017)

fig : Line follower combinational logic PCB

(2nd year 2017)

fig : Line follower robot logic development

(2nd year 2017)

fig : ATmega328 development board PCB

(2nd year 2017)

(2nd year 2017)

fig : IR sensor array PCB

(2nd year 2017)

fig : combination logic based line follower

robot with 1 bit memory PCB

(2nd year 2017)

fig : project day (2nd year 2017)

(combinational logic based line follower with 1 bit memory)

(2nd year 2017)

fig : Environmental data collection device

Barometric pressure, temperature , ultrasonic distance measurement

CO2 level measurement

(2nd year 2017)

fig : first year Arduino training ( 1st year 2016)